When comparing PAC and PVC chemical materials, it’s essential to understand their unique properties and applications. This blog will give you an in-depth analysis of these two kinds of materials.

Chemical Composition and Properties

Polyvinyl Chloride (PVC) and Polyaluminum Chloride (PAC) are distinct chemical materials known for their unique properties. This section explores their chemical composition and properties from two perspectives: molecular structure and physical properties.

Molecular Structure

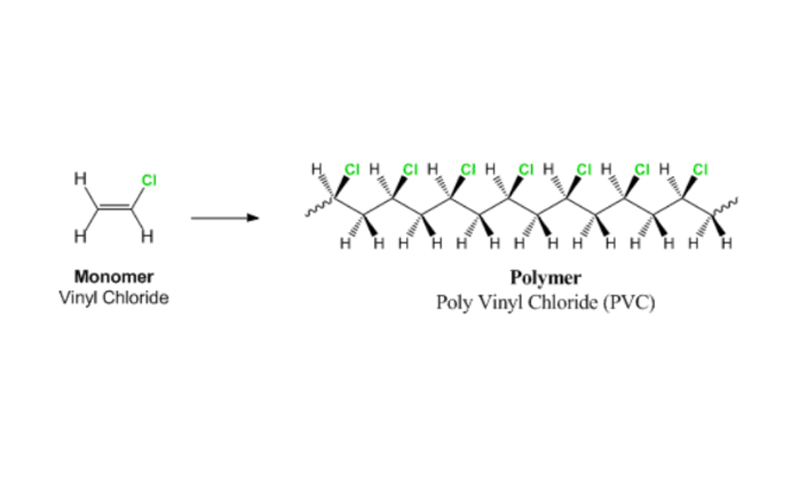

Polyvinyl Chloride (PVC) is a polymer formed from vinyl chloride monomers. The chemical structure consists of repeating units of C₂H₃Cl, connected by covalent bonds, creating a long chain polymer. Chlorine atoms in the structure provide thermal stability, making PVC resistant to fire and degradation.

Polyaluminum Chloride (PAC) is characterized by its complex polymeric structure containing aluminum and chloride ions. Its chemical formula varies, but it generally includes Al₂(OH)nCl₆-n, where ‘n’ ranges between 1 and 5. This allows PAC to exhibit strong coagulation properties, vital in many water treatment processes.

Physical Properties

PVC exhibits significant flexibility and strength, making it suitable for a wide range of applications. It has a density of about 1.3-1.45 g/cm³ and a melting point of approximately 100°C. PVC is known for its remarkable tensile strength and chemical resistance. These features make it a reliable choice for products like pipes, cables, and various construction materials.

PAC, on the other hand, is a yellowish powder or aqueous solution. It is known for its high density, around 1.2-1.5 g/cm³, and its strong coagulation capability. This material does not exhibit the same level of tensile strength or flexibility as PVC but is highly valued in treating polluted water due to its efficient chemical properties.

Applications in Various Industries

PVC is a versatile material that finds applications across numerous industries due to its unique properties such as durability, affordability, and chemical resistance. This section will explore its prominent uses in construction and plumbing, healthcare, and the automotive sectors.

Construction and Plumbing

In the construction industry, PVC plays a crucial role. PVC pipes are extensively used in plumbing systems for both residential and commercial buildings because they are lightweight, easy to install, and resistant to corrosion, reducing maintenance and replacement costs.

Additionally, PVC window frames offer excellent thermal insulation, which can lead to energy savings. PVC is also used for flooring due to its durability and ease of cleaning, making it suitable for high-traffic areas.

Healthcare

The healthcare industry also benefits significantly from the use of PVC. In medical settings, PVC is used to manufacture products such as blood bags, tubing, and IV containers due to its flexibility and ability to be sterilized. These products are critical in ensuring the safe and efficient delivery of medical services.

Automotive

In the automotive industry, PVC is valued for its durability and versatility. It is used in the manufacturing of interior trim, seating, and underbody coating due to its flexibility and resistance to wear and tear.

PVC’s insulating properties make it a preferred material for electrical insulation in vehicles, contributing to the reliability and safety of automotive electrical systems. The use of PVC in automotive components helps in weight reduction, leading to improved fuel efficiency.

Environmental Impact and Sustainability

Polyvinyl chloride (PVC) is widely used due to its versatility, but it raises significant environmental and health concerns. Understanding the impact of PVC, particularly in relation to alternatives like polyaluminum chloride (PAC), is essential for making informed decisions.

Health and Safety

PVC production and disposal release harmful chemicals, including chlorine and plasticizers like phthalates. These substances can have detrimental effects on both human health and the environment. Exposure to PVC by-products has been linked to respiratory issues and cancer, making it a considerable concern for communities near manufacturing sites. PAC, primarily used in water treatment, poses fewer health risks as it does not release toxic by-products.

In healthcare settings, PVC is often used in medical devices such as IV bags and tubing. This raises concerns about chemical leaching during patient care. Alternatives to PVC, which do not rely on harmful plasticizers, are being explored to improve safety standards in these environments.

Recycling and Disposal

Recycling PVC presents challenges due to the material’s complex chemical structure. It cannot be easily melted down and reformed without releasing hazardous substances. Consequently, much of the PVC waste ends up in landfills or incinerators, leading to environmental pollution and greenhouse gas emissions. Research suggests the classification of PVC as hazardous waste could further complicate disposal processes and hamper zero-waste initiatives

Conversely, PAC, being less hazardous, simplifies the recycling and disposal process. The lower environmental impact of PAC underscores the importance of developing and adopting materials that are easier and safer to recycle, aligning with sustainability goals.

Understanding these issues helps stakeholders make better choices concerning material use and disposal methods.

Manufacturing Processes and Material Comparison

This section explores the key differences between PAC and PVC in terms of their manufacturing processes and material properties.

PAC vs PVC

PAC (Polyaluminum Chloride) requires a complex chemical process for its production. It’s predominantly used as a coagulant in water treatment. The synthesis involves neutralizing Aluminum Hydroxide with Hydrochloric Acid. PAC excels in its high coagulation efficiency and lower sludge volume production compared to traditional coagulants.

PVC (Polyvinyl Chloride) is produced through polymerization of Vinyl Chloride Monomer (VCM). This process starts with the extraction of ethylene from natural gas or petroleum. Post extraction, VCM undergoes chemical reactions to form PVC. Known for its versatility, PVC is utilized in construction, piping, and medical equipment due to its rigidity and chemical resistance.