PVC pipes are a versatile component used in a wide range of construction and plumbing projects. Despite their widespread utility, PVC pipes often require stabilization to ensure they maintain their integrity and function efficiently. This blog will focus on how to stabilize PVC pipes effectively.

Understanding PVC Pipe Stabilization

Stabilizing PVC pipes involves protecting them from thermal and UV degradation to maintain performance and longevity. Proper stabilization enhances the mechanical properties and prevents discoloration.

Factors Affecting PVC Stability

PVC stability is influenced by thermal, UV, and chemical factors. Heat exposure during processing can cause the material to degrade, leading to discoloration and reduced mechanical strength. To counteract this, heat stabilizers are utilized.

UV radiation is another concern, especially for outdoor applications. UV stabilizers are necessary to protect PVC from sunlight damage. Chemical interactions with other materials can also impact stability. Non-toxic options are available to maintain safety standards in sensitive applications.

Importance of Proper Stabilization

Effective stabilization prevents degradation, ensuring the durability and safety of PVC pipes. It allows the material to maintain its flexibility, mechanical strength, and appearance over time. Inadequate stabilization can result in early failure, necessitating costly repairs or replacements.

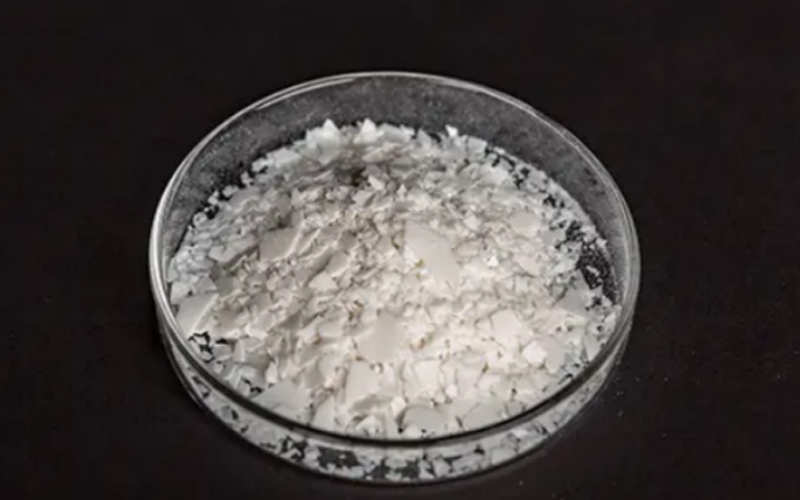

The use of mixed metal stabilizers, which often include compounds like calcium and zinc, is common for enhancing the durability of the pipes. Proper stabilization is also crucial for applications ranging from construction to healthcare, where PVC’s integrity is essential.

Methods of Stabilizing PVC Pipe

Stabilizing PVC pipe is crucial for ensuring that it maintains its integrity and functionality over time. This can be achieved through various methods, including the use of external supports, brackets, and straps, and embedding the pipe in concrete.

Use of External Supports

External supports are essential for maintaining the alignment and positioning of PVC pipes, especially in long runs or high-pressure applications. They reduce strain on the pipes and prevent sagging or bending. Supports like pipe cradles or hangers should be spaced appropriately along the pipe’s length to provide balanced support without causing stress at any single point.

When selecting supports, one should consider the pipe’s diameter, weight, and environmental conditions it will be exposed. Adjustable supports allow for changes in pipe position due to thermal expansion and contraction. Ensuring that supports are made from non-corrosive materials will help maintain the longevity of both the support and the pipe itself as well.

Securing PVC with Brackets and Straps

Brackets and straps are common methods for securing PVC pipes in both residential and industrial settings. They firmly anchor the pipes to walls, ceilings, or other structures, preventing movement that can lead to joint separations or leaks. To properly secure pipes, brackets, and straps should be placed at regular intervals, typically according to the pipe size and the weight of the fluid it carries.

Using heavy-duty brackets in areas under greater stress ensures durability and protection against external forces. One may consider brackets made from materials resistant to UV and chemical exposure for outdoor installations, helping to maintain performance in harsh conditions. Proper installation requires ensuring that fasteners are tightly secured to provide a stable and long-lasting setup.

Embedding PVC in Concrete

For underground or highly secured installations, embedding PVC pipe in concrete offers maximum stability. This method protects pipes from mechanical damage and environmental factors, ensuring the pipe’s integrity over time. When embedding pipes, it’s important to ensure that the concrete completely surrounds the pipe without air pockets that could compromise structural support.

Adequate spacing should be considered to allow for any potential expansion or contraction of the pipe due to temperature variations. The use of spacers can help maintain proper alignment during the pouring process. This method is effective for high-pressure applications or where significant external load resistance is necessary.

Materials and Tools Required

Stabilizing PVC pipe effectively involves selecting appropriate materials and tools. The choice of stabilizers and necessary installation tools are essential for proper support and reinforcement of PVC piping systems.

Choosing the Right Stabilizers

Several options are available when choosing stabilizers for PVC pipes. Spray foam is a popular choice as it fills the interior of the pipe, adding rigidity and support. This substance can be shaped and sanded as needed. Pipe cement is crucial for creating strong PVC joints; it ensures the connectors hold the pipes firmly in place.

Other materials like pool noodles can also provide external support. Cut pool noodles to fit around pipes, and use fasteners to attach them. This offers additional shock absorption and prevents rattling.

Necessary Tools for Installation

Several tools are necessary for PVC pipe installation and stabilization. A PVC pipe cutter ensures clean, precise cuts, reducing jagged edges that can weaken connections. A heat gun or torch can be useful when working with pipe cement, as slight heating may help joints form more securely.

In addition, a drill is often needed for creating holes for spray foam application or securing external stabilizers. Fasteners like screws and fender washers are essential when using pool noodles or other materials to attach them securely to walls. These tools ensure a stable and reliable PVC piping system.

Maintenance and Inspection

Regular maintenance and thorough inspection are crucial for ensuring the longevity and functionality of PVC pipe systems. This involves creating a consistent schedule for upkeep and recognizing potential issues before they escalate.

Regular Maintenance Schedule

Implementing a regular maintenance schedule for PVC pipes ensures that they remain in optimal condition. Monthly cleaning helps prevent dirt build-up and clogs. A mild detergent and warm water can be effective for cleaning; avoiding harsh chemicals will protect the integrity of the pipes.

Lubrication periodically is also essential to prevent cracking or breaking. This process involves applying appropriate lubricants to joint fittings, especially in areas with high stress or movement.

Checking for loose fasteners and adjusting them as needed can prevent instability within the piping system. Replacing worn-out components promptly will avert potential leaks or bursts that can cause significant damage.

Identifying Potential Issues

Early identification of potential issues in PVC piping is essential to prevent costly repairs. Regular inspections should focus on visible signs of damage, such as cracks, leaks, or loose connections. Utilizing a flashlight and mirror can aid in examining hard-to-reach places.

Listening to unusual sounds, such as whistles or hisses, might indicate air leaks or pressure build-up.

Fittings should be checked for debris accumulation, which can obstruct water flow over time. Addressing these blockages promptly is crucial to maintaining system efficiency. Keeping an eye on water pressure changes can also indicate internal obstructions.

Catastrophic failures can be minimized by taking timely corrective actions based on the inspection findings, ensuring the system remains robust and reliable.