PVC cling film has become an essential tool for both household kitchens and professional food service environments due to its versatility and effectiveness. This plastic wrap’s superior cling and puncture resistance keep food items fresh and protected. This blog will walk you through the realm of PVC cling film.

PVC Cling Film Overview

PVC cling film, made from polyvinylidene chloride, is commonly used for packaging food due to its excellent moisture barrier and fog resistance. Key characteristics and applications include its material properties, common uses, and production process.

Material Properties

PVC cling film offers high clarity and excellent cling properties. It is made from polyvinylidene chloride (PVC), which helps in maintaining food freshness. The material resists fog formation, allowing for clear visibility of the packaged items.

The film has a glossy appearance and is flexible, making it easy to wrap around various shapes. It starts to soften at around 60C/140F due to its high plasticizer content, which makes it suitable for a wide range of uses, except those involving high heat.

Common Uses

PVC cling film is widely used in the food industry. It is ideal for wrapping and storing perishable items such as fruits, vegetables, and meats. Its ability to cling tightly to containers and food items helps in preventing leakage and contamination.

Besides its use in homes, it is extensively used in catering and food service industries. However, it is not recommended for wrapping oily and pure-fat foods due to compatibility issues with these substances.

Production Process

The production of PVC cling film involves the polymerization of vinyl chloride. During this process, raw materials are mixed and heated to form PVC resin. The resin is then combined with plasticizers, stabilizers, and other additives to enhance its flexibility and durability.

Once the mixture reaches the desired consistency, it is extruded into thin sheets and cooled. The final product is wound into rolls and packaged for distribution. This process ensures that the film retains its essential properties, such as clarity and cling strength.

Health and Safety

PVC cling film is commonly used in food packaging due to its flexibility and ability to extend the shelf life of food. It is important to navigate both regulatory standards and everyday safety tips to ensure its safe usage.

Regulatory Standards

PVC cling film must adhere to specific regulatory standards to ensure it is safe for use with food. In the European Union and the United Kingdom, it is regulated to guarantee that the migration of chemicals from plastic into food remains within safe levels. Studies confirm that PVC cling film used for food contact poses no health risks and meets stringent EU regulations.

In the United States, the Food and Drug Administration (FDA) oversees its safety, ensuring that the materials used are food-grade and not harmful when used as intended. These standards help in maintaining public health and instilling consumer confidence in using PVC cling film for food storage.

Safety Tips for Consumers

One should always look for food-grade PVC cling film and check the manufacturer’s instructions for usage. This ensures that the material meets the necessary safety standards. It is also crucial to avoid using PVC cling film in ovens unless specified by the manufacturer, as it can melt and contaminate food.

When using PVC cling film in microwaves, ensure it is labeled microwave-safe to prevent chemical leaching. One should also avoid wrapping hot food items directly with the film to minimize exposure to any potential chemical migration. What’s more, proper storage of PVC cling film away from heat and direct sunlight can maintain its integrity and safety for food contact.

PVC Stabilizer’s Effect on PVC Cling Film

Understanding PVC stabilizers and how they influence PVC cling film is critical for ensuring efficient and safe food packaging. This section will explore the types of stabilizers used and their specific effects on the cling film.

PVC Stabilizer

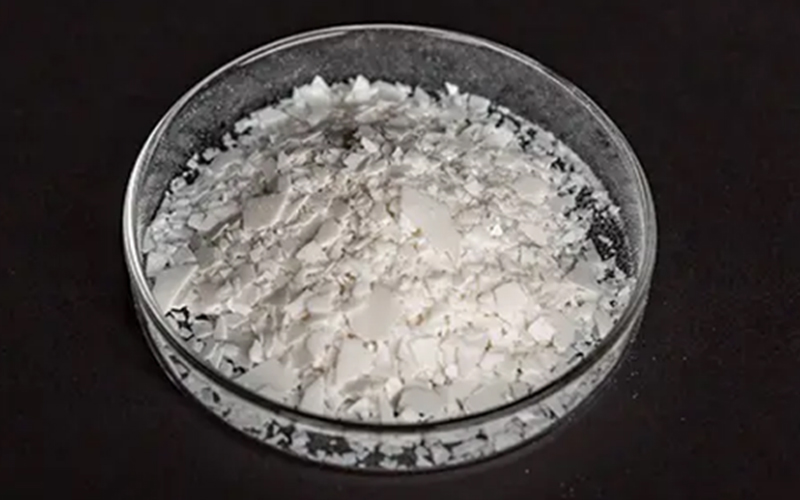

PVC stabilizers are compounds added to polyvinyl chloride (PVC) to enhance its durability, heat resistance, and overall performance. Common types include calcium-zinc, Barium-zinc, and K-Zn stabilizers. These additives prevent degradation during processing and usage by neutralizing hydrochloric acid released when PVC is heated.

Calcium-zinc stabilizers are favored for their non-toxic nature, making them ideal for food-related uses like cling film. Moreover, lead stabilizers, though effective, are being phased out due to toxicity concerns. Finally, organotin stabilizers offer excellent heat stability and clarity, crucial traits for maintaining the film’s properties during storage and microwave heating.

Effect on PVC Cling Film

The inclusion of stabilizers greatly influences the physical and chemical properties of PVC cling film. Enhanced durability and heat resistance mean the film remains intact and functional under various conditions, including refrigeration and microwave usage. This durability ensures extended shelf life and reduces food waste.

Stabilizers also impact the film’s transparency and flexibility. High-quality stabilizers maintain the film’s clarity, essential for visually inspecting packaged food. Flexible films provide a tight seal, critical for preserving food freshness and preventing contamination. Additionally, stabilizers improve the film’s resistance to moisture and oxygen, increasing its effectiveness in preserving perishable goods.

In sum, proper selection and use of PVC stabilizers are crucial for producing high-performance cling films that meet safety and functionality requirements.