Heat stabilizers are essential additives that protect polyvinyl chloride (PVC) from thermal degradation during processing and use. These stabilizers are vital for preventing discoloration, mechanical strength loss, and performance decline in PVC materials. This blog will walk you through the topic of heat stabilizers.

Overview of Heat Stabilizers for PVC Pipes

Heat stabilizers play a crucial role in the manufacturing and longevity of PVC pipes. These additives protect polyvinyl chloride (PVC) from degrading under high temperatures encountered during processing and use.

PVC, a widely used commercial plastic, is thermally unstable at high temperatures. The selection and formulation of heat stabilizers are essential to maintain PVC’s durability and performance characteristics.

- 1. Metal-based Stabilizers:

- Lead-based: Historically widely used but now phasing out due to environmental concerns.

- Calcium-zinc: Common alternative, more environmentally friendly.

- 2. Organic-based Stabilizers:

- Increasingly popular for being eco-friendly.

- Efficient in preserving the integrity and appearance of PVC.

- 3. Organophosphites:

- Protect polymers during processing.

- Enhance overall performance and durability.

Key Benefits:

- 1. Protection from Heat Degradation:

- Maintains polymer strength and elasticity.

- Prevents discoloration and brittleness.

- 2. Longevity:

- Extends the lifespan of PVC pipes.

- Ensures reliable performance in various applications.

Manufacturers continue to innovate in this area, developing new stabilizers that meet both regulatory standards and market demands. This evolution ensures that PVC pipes remain a reliable and sustainable choice in various industries.

Types of Heat Stabilizers

Heat stabilizers are essential additives that enhance the thermal stability of PVC pipes, ensuring longevity and performance. Various types of heat stabilizers are utilized, each with distinct characteristics and applications.

Organotin Stabilizers

Organotin stabilizers are primarily used in rigid PVC applications like pipes, profiles, and window frames.

They provide excellent heat stability and weather resistance, making them suitable for outdoor applications. These stabilizers also offer superior clarity and transparency, beneficial for specific product requirements.

One key advantage of organotin stabilizers is their effectiveness in small quantities. This makes them an efficient choice for manufacturers. Despite their higher cost compared to other stabilizers, their efficiency and performance justify the investment.

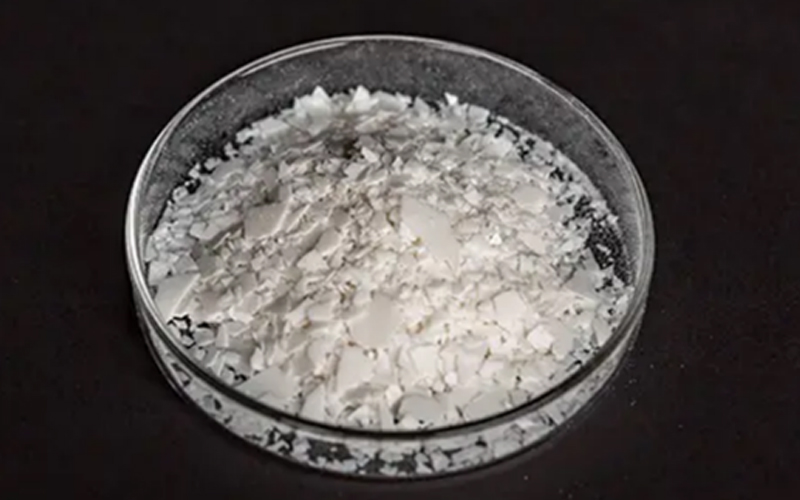

Calcium-Based Stabilizers

Calcium-based stabilizers, often combined with zinc, are a preferred choice for numerous PVC applications.

They are considered environmentally friendly, as they do not contain heavy metals. These stabilizers offer balance in heat stability and mechanical properties, making them versatile for both rigid and flexible PVC products.

Calcium-based stabilizers also excel in electrical insulation, adding another layer of utility. These stabilizers are often used for pipes, cables, and flooring, among other applications.

Lead-Based Stabilizers

Lead-based stabilizers have been traditionally utilized in PVC applications due to their cost-effectiveness and reliable performance.

They offer excellent heat stability and electrical insulation properties, critical for wires and cables.

However, the use of lead-based stabilizers has significantly declined due to health and environmental concerns. Regulatory restrictions in many regions have pushed industries to seek alternative stabilizers. Despite their decline, they remain in use in specific regions and applications.

Mixed Metal Stabilizers

Mixed metal stabilizers combine different metal ions, such as barium, zinc, and calcium, to provide balanced heat stabilization.

These stabilizers are versatile, catering to both rigid and flexible PVC applications. They offer good thermal stability and weather resistance, similar to organotin stabilizers, but at a lower cost.

Mixed metal stabilizers are often used in applications requiring enhanced performance without the environmental concerns associated with lead-based options.

Mechanism of Heat Stabilization

Heat stabilizers protect PVC pipes from degradation caused by high temperatures encountered during processing and use. The primary mechanisms involve preventing dehydrochlorination and neutralizing hydrochloric acid.

Preventing Dehydrochlorination

Dehydrochlorination is the process where PVC loses hydrogen chloride (HCl) when exposed to high temperatures, leading to polymer degradation. This can result in discoloration and a reduction in mechanical properties. Heat stabilizers incorporate compounds that can inhibit this reaction. For instance, calcium and zinc-based stabilizers are effective in this regard, as they prevent the formation of conjugated double bonds which cause discoloration. These stabilizers also help maintain the structural integrity of the PVC pipes during their lifetime, ensuring durability and longevity.

Neutralizing Hydrochloric Acid

As PVC degrades, hydrochloric acid (HCl) is released, which can further catalyze the degradation process. Heat stabilizers neutralize this acid to protect the polymer. Lead-based stabilizers have traditionally been used for this purpose, but safer alternatives like calcium/zinc formulations are now more commonly used. These stabilizers react with the evolved HCl to form stable, non-volatile compounds, effectively halting further degradation. This neutralization is essential for maintaining the heat stability and long-term performance of PVC pipes, especially in demanding applications. By selecting appropriate stabilizers, the PVC manufacturing process can be optimized to produce pipes with excellent thermal stability and mechanical properties.

Considerations for Selecting PVC Pipe Heat Stabilizers

Selecting an appropriate heat stabilizer for PVC pipes involves evaluating thermal stability requirements, environmental and health factors, and compatibility with PVC processing methods.

Thermal Stability Requirements

Thermal stability is crucial because PVC degrades at high temperatures. The stabilizer must effectively maintain the integrity of PVC during both processing and end-use. Heat stabilizers are chosen based on their ability to prevent discoloration, maintain mechanical properties, and avoid decomposition at specific processing temperatures.

Various types of stabilizers, such as tin-based, calcium-zinc, and organic stabilizers, are tailored for different thermal conditions. For example, tin-based stabilizers offer strong thermal performance but may be more costly. Understanding the operational temperature range, typically around 60°C (140°F), is essential in selecting an appropriate stabilizer.

Environmental and Health Considerations

The selection of heat stabilizers must also take into account their environmental and health impacts. Traditional lead-based stabilizers are being phased out due to toxicity concerns. In Europe, initiatives like Vinyl 2010 aim to eliminate lead-based stabilizers, promoting safer alternatives such as calcium-zinc and organic options.

Lead-free stabilizers are preferred in applications requiring strict environmental compliance. Additionally, regulations regarding the disposal and recycling of PVC products can influence stabilizer choices. Ensuring that stabilizers do not release harmful substances during the life cycle of the product is critical.

Compatibility with PVC Processing

Compatibility with the specific PVC processing method is another key consideration. PVC can be processed through injection molding, extrusion, and calendaring, each requiring different stabilizer characteristics. For example, stabilizers must be able to withstand the shearing forces and temperature variations inherent in these processes.

Stabilizers for PVC must integrate well without causing defects or affecting the final product quality. Factors such as ease of dispersion, influence on curing time, and interaction with other additives need to be evaluated. This ensures that the stabilizer works effectively throughout the production cycle, resulting in a durable and stable PVC product.