PVC leather, also known as polyvinyl chloride leather, is a synthetic material widely regarded as an affordable and durable alternative to genuine leather. This in-depth blog will guide you through the exploration of PVC leather.

Understanding PVC Leather

PVC leather, or polyvinyl chloride leather, is a ubiquitous synthetic alternative to genuine leather commonly used in a multitude of products such as furniture, car interiors, and accessories. This material, known for its durability and ease of maintenance, offers a cost-effective and versatile option in the market.

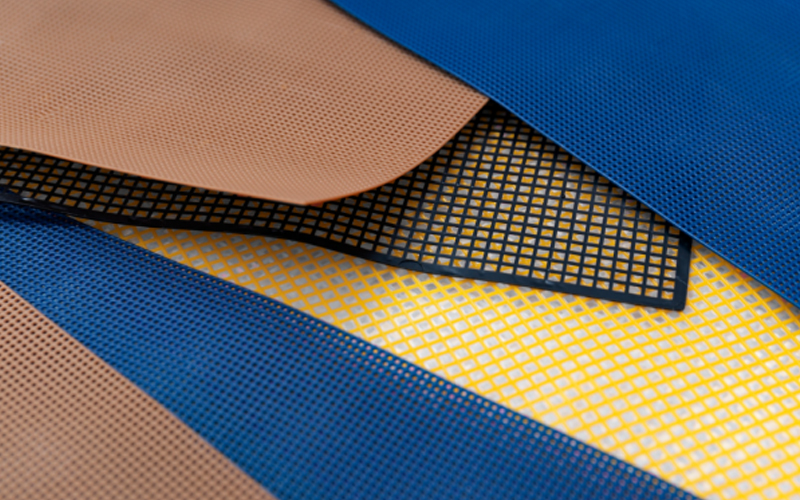

Composition and Types

PVC leather is constructed from a base layer of polyester fibers coated with a blend of PVC resin, plasticizers, and other additives, which provide flexibility and color. The surface is then textured to mimic the look of genuine leather. There are two primary types in the market: calendered PVC leather and cast PVC leather. Calendered PVC is made by spreading the PVC mixture on a backing, while cast PVC is made by pouring the liquid PVC onto a mold.

PVC Leather vs Genuine Leather

When comparing PVC leather to genuine leather, one immediately notices differences in breathability, feel, and durability. PVC leather is less breathable due to its plastic coating and might feel stiffer than genuine leather. However, it excels in its resistance to stains and its water-repellent nature. Unlike genuine leather, which can age with a unique patina, PVC leather maintains a consistent appearance over time.

Environmental Impact

The environmental impact of PVC artificial leather is a contested topic. Production involves the use of chlorine, which forms dioxins, potent toxins that can be harmful to both the environment and human health. However, advancements in manufacturing have led to the development of eco-friendly PVC leathers that aim to reduce toxic output. The durability and long life-span of PVC leather also contribute to its sustainability, as it doesn’t require frequent replacement.

By understanding the composition and types of PVC leather, comparing it to genuine leather, and considering its environmental impact, one can make informed decisions about its use in various applications.

Benefits of PVC Leather

PVC leather offers a range of advantages that cater to durability and practicality, particularly in its resistance to various forms of wear and its ease of maintenance.

Durability and Resistance

PVC leather is known for its remarkable durability. It is a material with a high degree of resistance to hydrolysis and UV rays, which contributes to its longevity. This synthetic leather is also anti-bacterial and anti-mildew, ensuring that it stands up well against these common issues. Its construction allows it to resist wear, making PVC leather a suitable choice for items that are used frequently or in harsh conditions.

Maintenance and Cleaning

One of the most appealing features of PVC leather is how easy it is to clean. Unlike other materials, it does not absorb spills, which makes it highly stain-resistant. Cleaning usually requires nothing more than a damp cloth. Moreover, being waterproof, PVC leather does not get soaked or damaged when exposed to liquids, making it ideal for furniture, upholstery, and vehicle interiors where spills may occur.

Applications of PVC Leather

PVC leather’s versatility allows it to be widely used across various industries due to its durability, ease of maintenance, and affordability.

Fashion Industry

In fashion, PVC leather is often utilized for making garments such as jackets and pants, which demand a leather-like aesthetic without the high cost of genuine leather. Bags and shoes also frequently feature PVC leather due to its ability to resist moisture and mimic the texture of real leather, providing fashion accessories that are both stylish and practical.

Furniture and Upholstery

The furniture sector relies heavily on PVC leather for upholstery purposes. It is a preferred material for couches and chairs as it is easier to clean and maintain than traditional leather. Its resistance to wear and tear, along with a variety of design options, helps household furniture withstand daily use while maintaining an elegant look.

Automotive Industry

In the automotive industry, PVC leather is regularly used to upholster car interiors. It stands up to the constant use and exposure to sunlight better than some other materials, which is essential for car seats and dashboards that need to endure a range of temperatures and conditions while still maintaining an appearance that is as close to genuine leather as possible.

Production and Manufacturing

The manufacturing of PVC leather is a detailed process that involves specific raw materials and precision-driven technology. It represents a blend of science and craftsmanship, producing a material that offers flexibility and practicality for various applications.

Raw Materials and Processes

Manufacturers begin the production of PVC leather by sourcing raw material such as raw PVC and a base of either woven or non-woven fabric. The process starts with a PVC mixture that incorporates pvc stabilizer to enhance its flexibility. The mixture is then applied, often as a coating, onto the base fabric. The coated fabric is subjected to heat and pressure to bond the materials together, resulting in a sturdy yet flexible composite known as PVC leather.

The production process may vary slightly depending on the desired characteristics of the finished product. For instance, manufacturers might adjust the levels of plasticizers to control the material’s softness and flexibility. The consistency and quality of the base fabric—whether woven or non-woven—also play a crucial role in determining the durability and appearance of the PVC leather.

Technological Innovations

In pursuit of superior performance and sustainability, technological innovations are constantly reshaping the PVC leather manufacturing landscape. Strides in technology allow for more efficient use of energy and resources during production, enhancing the material’s eco-friendliness and appeal to environmentally conscious consumers.

Contemporary manufacturers have improved the production process of PVC leather by developing advanced coating techniques and utilizing high-quality polyurethanes. Resulting in a man-made product, these pvc stabilizer items exhibit enhanced attributes, such as a reduced environmental impact and increased longevity. Implementing these technological advancements, manufacturers can create PVC leather that closely imitates the qualities of natural leather, promoting its widespread use across various industries.

The Effect of PVC Stabilizer

Stabilizers play a significant role in enhancing the texture and appearance of PVC leather, making it a popular faux leather material.

Stabilizers are added to PVC to improve its durability and performance. They work by preventing the degradation of the vinyl fabric when exposed to heat or ultraviolet light. With proper stabilization, PVC leather maintains its flexibility and smoothness, akin to natural leather like cowhide.

- Impact on Texture and Breathability: Without stabilizers, the PVC would become brittle and less dense. Stabilizers ensure that the texture remains pliable, although it must be noted that PVC leather typically exhibits less breathability compared to natural leather types.

- Environmental Consideration: While stabilizers improve the functionality of PVC leather, discussing whether they make the material environmentally friendly is essential. Some concerns have been raised about the environmental impact of PVC and the additives used.

- Resistance to Weathering: Stabilizers are particularly beneficial in enhancing the material’s resistance to weathering, hence extending its usable life and preserving its aesthetics. This property is important for items prone to outdoor exposure, where maintaining the appearance of leather is key.

In summary, the incorporation of stabilizers into the production of PVC leather adds value by augmenting its properties, thus making it a practical and attractive imitation leather option. However, one should also weigh the environmental considerations linked with the use of PVC and its additives.

If you are looking for a PVC manufacturer, look no further than Baisha Chemicals, a leading company specializing in top-tier PVC in top-tier chemicals. With a wealth of expertise and cutting-edge technology, Baisha offers a comprehensive range of stabilizers tailored to meet your specific requirements. If you’re in need of PVC, Baisha’s PVC ensure exceptional performance and reliability for your PVC applications.