Polyvinyl Chloride, commonly known as PVC, is a versatile plastic made from vinyl chloride monomers combined with various additives. This material, characterized by its durability and affordability, is essential in many industries including construction and healthcare. This blog will walk you through the composition of PVC and its relevant topics.

What Is PVC Made Out of

Polyvinyl Chloride (PVC) is composed of vinyl chloride monomers and various additives that enhance its properties. The polymerization of vinyl chloride into PVC and the addition of stabilizers and plasticizers are critical steps in producing this versatile material used in numerous applications. This section will focus on vinyl chloride monomer and the polymerization process.

Vinyl Chloride Monomer: The Building Block

Vinyl Chloride Monomer (VCM) is the essential building block of PVC. It is a colorless gas with a mild, sweet odor, composed of two carbon atoms, three hydrogen atoms, and one chlorine atom. The chemical formula for vinyl chloride is C₂H₃Cl.

VCM is produced through the thermal cracking of ethylene dichloride, which is derived from petroleum. The vinyl chloride gas is then cooled and liquefied to be used in the polymerization process. Safety precautions are critical when handling vinyl chloride due to its potential health risks, including its classification as a carcinogen.

Polymerization Process: From Monomer to Polymer

The polymerization of vinyl chloride into PVC can be achieved through suspension, emulsion, or bulk polymerization techniques. In suspension polymerization, vinyl chloride monomers are suspended in water and polymerized in the presence of a catalyst, creating polyvinyl chloride.

Emulsion polymerization involves emulsifying the vinyl chloride monomer in a water-based solution with surfactants, leading to a finer polymer dispersion. Bulk polymerization, though less common, directly polymerizes the monomer without solvents. The resulting PVC can be rigid or flexible, depending on the additives used.

During polymerization, the vinyl chloride molecules link together to form long-chained polymers. The chemical structure of PVC is represented as: [-CH₂-CHCl-]ₙ, where ‘n’ denotes the number of repeating units in the polymer chain.

Role of Additives in PVC

Additives play a significant role in enhancing the properties of PVC. Plasticizers, such as phthalates, are added to make PVC flexible and elastic. Plasticizers increase the material’s flexibility by weakening the intermolecular forces between polymer chains.

Stabilizers, including lead and tin compounds, are crucial in preventing PVC degradation. They protect the polymer from heat and UV radiation, ensuring the material’s durability. Other common stabilizers are calcium-zinc and tin-based compounds.

Various other additives, including pigments, lubricants, and impact modifiers, can be incorporated to achieve desired characteristics. Pigments provide color, while lubricants assist in processing. Impact modifiers improve the material’s toughness, making it ideal for applications like window frames and pipes.

PVC Production and Manufacturing

Polyvinyl chloride (PVC) is produced through a series of industrial processes that transform raw materials into a versatile plastic. Key aspects include the production methods and the environmental and health considerations associated with PVC.

Industrial Production Methods

PVC production begins with the preparation of vinyl chloride monomer (VCM). Ethylene and chlorine are combined to form ethylene dichloride (EDC), which is then further processed to create VCM. This monomer is essential for the polymerization process.

During polymerization, VCM molecules are linked together to form long chains, creating the polymer PVC. This can be done using suspension, emulsion, or bulk polymerization techniques. Each method offers distinct advantages based on the intended application of the PVC.

Suspension polymerization is the most common technique, providing a powder form of PVC that is useful in many products. Emulsion polymerization produces a finer, paste-like resin that is ideal for coatings and fabric applications. Bulk polymerization, although less common, offers a streamlined process with fewer impurities.

Environmental and Health Considerations

The production and manufacturing of PVC raise several environmental and health concerns. One of the primary issues is the release of dioxin, a byproduct of chlorine production and combustion of PVC. Dioxins are toxic and can accumulate in the food chain, posing risks to human health and wildlife.

PVC is also associated with other harmful substances like phthalates and heavy metals, used as additives to enhance its properties. These can leach out and cause environmental pollution and health risks.

Sustainability in PVC production is a growing focus, with efforts to reduce harmful emissions and recycle PVC products. Advances in green chemistry and alternative materials are helping to address some of these concerns, making the industry more environmentally responsible.

Applications of PVC

PVC is known for its versatility and is used in numerous sectors due to its durability, cost-effectiveness, and adaptability. Its applications range from construction materials to medical devices.

What Is PVC Pipe Made of

PVC pipes are primarily made from a combination of polyvinyl chloride resin and various additives. These additives typically include stabilizers, lubricants, and plasticizers, which enhance the material’s properties.

Rigid PVC pipes are commonly used in plumbing and industrial applications due to their high durability and resistance to corrosion. They also serve in electrical wiring and cabling because of their excellent insulation properties.

Flexible PVC pipes, reinforced with additional compounds, are often utilized in irrigation, medical tubing, and automotive applications, including fluid transfer and ventilation systems.

What Is PVC Board Made of

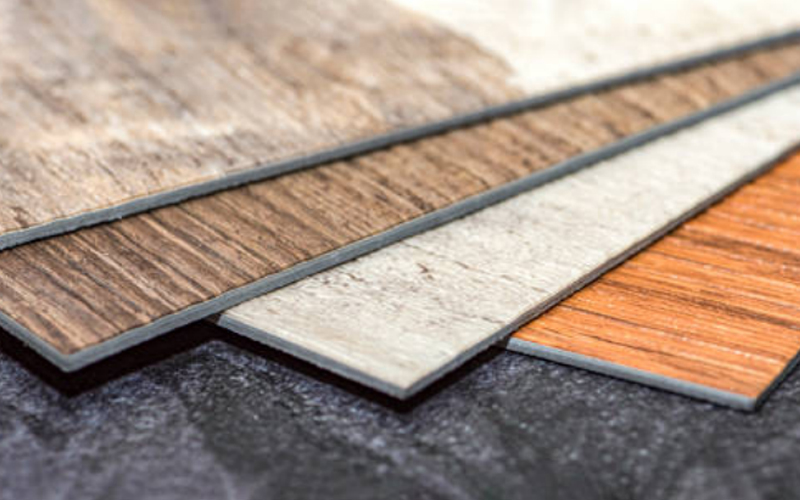

PVC boards are manufactured using a blend of polyvinyl chloride polymer and other components such as stabilizers, fillers, and pigments. These materials are extruded into rigid, lightweight boards that are resistant to moisture and decay.

Commonly used in the construction industry, PVC boards serve as substitutes for traditional wood and metal in applications like window frames, doors, and trim. They are also favored for their ease of installation and maintenance.

In industrial settings, PVC boards are used for signage, paneling, and other applications where durability and weather resistance are crucial factors.

What Is PVC Leather Made of

PVC leather, also known as vinyl leather, is made from a polyester fabric coated with polyvinyl chloride and plasticizers. The coating provides a flexible, water-resistant surface that mimics the look and feel of natural leather.

This material is widely used in the automotive industry for car upholstery, offering a durable and easy-to-clean alternative to traditional leather. It is also prevalent in the furniture industry for making chairs, sofas, and other upholstered items.

In addition, PVC leather is used in fashion for products like bags, belts, and shoes, combining style with practicality and affordability.