PVC pipe, made from polyvinyl chloride, is a staple in modern plumbing and construction. Known for its durability and cost-effectiveness, PVC pipe is a versatile material utilized in residential, industrial, and municipal applications. This blog will offer a detailed introduction to PVC pipes, focusing on their properties, applications and other aspects.

Understanding PVC Pipes

Polyvinyl chloride (PVC) pipes are widely used in various plumbing, irrigation, and construction applications due to their durability and versatility. These pipes come in different types and sizes, each with specific characteristics and uses. This section will center on their types and sizes.

Composition and Types

PVC pipes are made from polyvinyl chloride, a thermoplastic material derived from vinyl chloride monomers. There are several types of PVC, including:

· Rigid PVC (PVC-U): This unplasticized form is used for water distribution and irrigation.

· Flexible PVC: Contains plasticizers, making it suitable for medical tubing and other flexible applications.

· Chlorinated PVC (PVC-C): This type is used in hot water distribution due to its heightened resistance to heat.

· Molecularly Oriented PVC (PVC-O): Has improved strength and ductility, often used in high-pressure water systems.

Generally, each type serves a specific purpose based on its physical properties, such as rigidity or flexibility, and resistance to different environmental factors.

Dimensions and Sizing

PVC pipes use a nominal system for standard sizing, meaning that parts with the same size in their name will be compatible with each other. The dimensions of PVC pipes are defined by both the inside diameter (ID) and outside diameter (OD). For instance:

· Sizes: Range from ½-inch to 5-inch for household plumbing

· Schedule 40 and Schedule 80: Schedule 40 has thinner walls compared to Schedule 80, which can handle higher pressures (210 to 1230 PSI) and is often colored dark gray.

Moreover, accurate measurements are crucial for successful installations, which ensures that fittings like couplings and elbows match perfectly with the pipe sizes. Key measurements include the outside diameter, the inside diameter, and the wall thickness of the pipes.

Durability and Applications

PVC pipes offer impressive durability due to their resistance to chemicals, impact, temperature, and pressure. These properties make them suitable for a range of applications across various industries. This segment will revolve around the durability of PVC pipes and how this property is applied across varying fields.

Chemical and Impact Resistance

PVC pipes are known for their chemical resistance. They can withstand a variety of acids, bases, and salts without deteriorating. This capability makes them ideal for carrying chemicals in industrial applications and sewage systems.

Additionally, PVC pipes exhibit significant impact resistance. They can endure external forces without cracking or breaking, which is crucial for subterranean installations and situations where pipes may be exposed to physical stress. This robustness is why PVC is favored for water distribution and irrigation systems.

Temperature and Pressure Tolerance

Different types of PVC pipes offer varying levels of temperature and pressure tolerance. For instance, C-PVC (Chlorinated PVC) is designed to handle higher temperatures, making it suitable for hot water systems.

Moreover, Schedule 80 PVC pipes are thicker and can tolerate higher pressure, which is essential for applications requiring the transport of liquids under extreme conditions. Such adaptability allows PVC pipes to serve in both domestic and industrial settings, including situations where wastewater in domestic lines and high-pressure industrial fluids need reliable conveyance.

Usage in Various Industries

The versatility of PVC pipes means they find use in multiple sectors. In the construction industry, they are employed for plumbing and electrical conduit systems. In agriculture, PVC is a reliable choice for irrigation systems due to its longevity and resistance to environmental stress.

Additionally, municipalities use PVC pipes extensively in water distribution and sewage systems. Their chemical resistance ensures longevity even when exposed to various effluents.

Finally, industrial applications benefit from PVC’s durability and ability to transport a variety of substances safely, including corrosive chemicals and high-temperature fluids. These characteristics ensure PVC pipes remain a staple in numerous essential services.

PVC Pipe Specifications

PVC pipe specifications include details on schedules, pressure ratings, wall thickness, and measurements. These specifications guide the selection of PVC pipes for various applications to ensure appropriate strength and durability.

Schedules and Ratings

PVC pipes come in various schedules, primarily Schedule 40, Schedule 80, and Schedule 120. Schedule 40 pipes are common for residential use, known for their thinner walls and lower pressure ratings. They typically handle pressures ranging from 110 to 450 PSI, depending on the diameter.

Schedule 80 pipes have thicker walls than Schedule 40, offering higher pressure resistance, often used in industrial environments. They support pressure ratings from 210 to 1230 PSI, suitable for handling higher water pressure and harsher conditions.

Schedule 120 pipes feature the thickest walls, designed for extreme pressure applications. These pipes are less common but essential for specific scenarios where high-pressure resistance is critical.

Measurements and Standards

PVC pipe measurements follow nominal sizing, meaning the nominal size doesn’t match the actual dimensions. For instance, a 1-inch PVC pipe has an actual outside diameter of 1.315 inches and an inside diameter of about 1.029 inches.

Wall thickness increases with the scheduled number. For example, Schedule 40 pipes have thinner walls compared to Schedule 80, which in turn has thinner walls compared to Schedule 120.

A dimensional chart provides detailed measurements and can help users select the correct pipe size for specific applications. Moreover, proper measurement ensures compatibility with fittings and adherence to ASTM standards, such as ASTM D1784 for cell classification and ASTM D792 for specific gravity. In practice, accurate measurement is crucial, ensuring the system’s integrity under expected pressure ratings and obstacles like water pressure surges.

The Importance of PVC Stabilizers

PVC stabilizers play unignorable roles in the effectiveness and longevity of PVC pipes. This section will elaborate on this topic, focusing on how PVC stabilizers enhance the durability of PVC pipes.

Enhancing Longevity and Durability

PVC stabilizers are essential for improving the lifespan and durability of PVC pipelines. One of the primary functions of PVC stabilizers is to prevent the degradation of PVC material. Over time, exposure to UV radiation and thermal stresses can cause PVC pipes to break down, reducing flexibility and making it easier to crack. Stabilizers inhibit these processes by neutralizing harmful reactions and protecting against external stresses. Besides, their excellent lubrication system can effectively prevent the problem of bleeding during processing.

Types of PVC Stabilizers Used in PVC Pipes

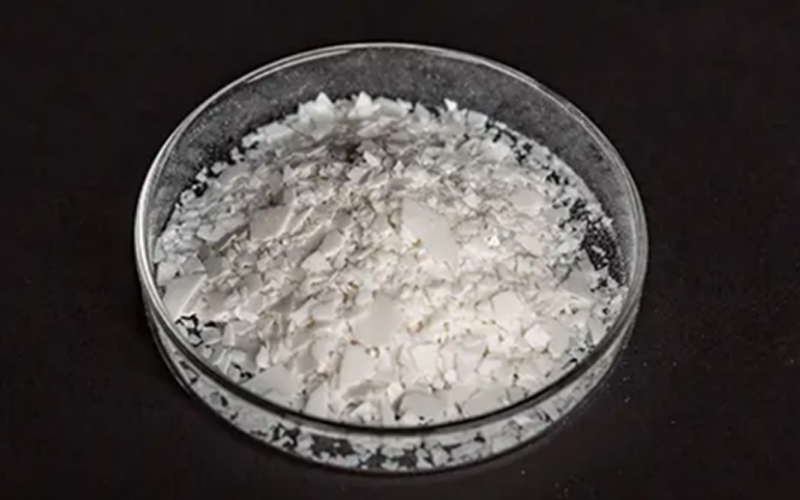

There are many kinds of PVC stabilizers and two of them are widely used in PVC pipes: calcium-zinc stabilizers and organotin stabilizers.

Calcium-zinc stabilizers provided by companies like Baisha are popular for their non-toxic properties and effectiveness in providing long-term protection to PVC pipes. They can effectively improve the processing efficiency and prevent bleeding during the process. Ca-Zn stabilizers are also effective in reducing the cost of PVC production.

Organotin stabilizers are another commonly used type in PVC pipe manufacturing. They are known for their excellent heat stability and efficiency in preventing degradation. Organotin compounds enhance the performance of PVC pipes by stabilizing them during both processing and end-use. These stabilizers are particularly useful in high-temperature applications and help extend the lifespan of the pipes by maintaining their structural properties over time.