Polyvinyl chloride (PVC) is a versatile plastic widely used in various industries due to its durability and cost-effectiveness. PVC scrap material, often generated from manufacturing processes and post-consumer goods, has significant value because it can be repurposed into new products. PVC scrap is transformed into pellets or regrind material, which are then used to produce items such as pipes, flooring, and roofing membranes. This in-depth blog will guide you through the exploration of PVC scrap material.

PVC Composition and Properties

Polyvinyl chloride is a highly versatile and durable material, making it valuable for numerous applications. Its chemical structure and recycling potential significantly impact both its functionality and environmental footprint.

Chemical Structure and Durability

PVC is composed of polymerized vinyl chloride monomers. The chemical formula is (C2H3Cl)n. This structure, combined with the use of various additives, grants PVC its notable properties.

Additives are crucial as they enhance its flexibility, durability, and resistance to environmental factors. For example, plasticizers make the material more flexible, while stabilizers improve its resistance to heat and UV radiation.

PVC is known for its durability. It resists weathering, chemical rotting, corrosion, and abrasion, making it suitable for long-lasting outdoor products. Building materials such as pipes, window frames, and roofing membranes benefit from these properties.

Environmental Impact and Recycling

The environmental impact of PVC is a significant consideration due to its widespread use. PVC production involves the release of some hazardous chemicals. However, recycling can mitigate its environmental footprint.

PVC is recyclable and can be processed into new products multiple times without significant degradation of its properties. Post-consumer PVC can be used in secondary applications such as flooring, pipes, and other construction materials, reducing waste and conserving resources.

Recycling initiatives must address the removal of additives, which can complicate the recycling process. However, advancements in recycling technology are improving the efficiency and effectiveness of this process, promoting a more sustainable use of PVC.

Overall, understanding the composition and properties of PVC is essential for leveraging its benefits while managing its environmental impact.

Recycling Processes for PVC Scrap

PVC scrap can be recycled using mechanical and chemical methods. Each approach has its unique advantages and intricacies, and is crucial for reducing waste and promoting sustainability.

Mechanical Recycling Techniques

Mechanical recycling involves grinding PVC scrap into a fine powder form. This process includes collecting PVC waste, cleaning it to remove contaminants, and then shredding it into smaller pieces. The clean, shredded PVC is reprocessed into new products by heating and melting.

These techniques are straightforward and cost-effective. Mechanical recycling maintains the polymer’s structure, allowing for the creation of high-quality recycled products. It is commonly utilized by recycling centers to handle pre-consumer and post-consumer waste efficiently.

This method also conserves energy compared to producing virgin PVC. While mechanical recycling is effective, it may not be suitable for all types of PVC scrap, especially if it is heavily contaminated.

Chemical Recycling and Advanced Methods

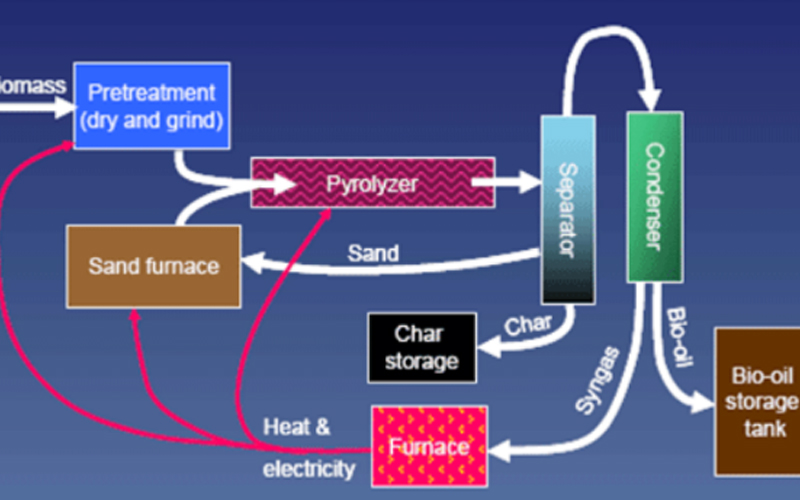

Chemical recycling involves breaking down the polymer chains of PVC through methods such as pyrolysis and hydrolysis. Pyrolysis heats PVC in the absence of oxygen, converting it into useful products like fuel and feedstock. Hydrolysis, on the other hand, uses water to break chemical bonds, producing hydrochloric acid and other valuable compounds.

Advanced methods like these are more adaptable to various types of PVC scrap. They can handle contaminated materials that mechanical recycling cannot process efficiently.

Chemical recycling is more resource-intensive, often requiring sophisticated facilities and additional energy. However, it enables the transformation of PVC waste into a broad range of materials, making it a critical component in the overall recycling strategy for PVC. Research in this field continues to improve efficiency and outcomes.

Applications of Recycled PVC

Recycled PVC is utilized in a range of industries to create durable and versatile products, particularly in construction and the manufacture of consumer goods.

Construction and Building Materials

In the construction industry, recycled PVC is frequently used for creating pipes, window profiles, and flooring.

Pipes made from recycled PVC are durable and resistant to corrosion. These pipes are commonly used in plumbing and drainage systems because of their long lifespan and strength.

Window profiles are another significant application. Recycled PVC is shaped into frames that provide excellent insulation and durability. These frames help in creating energy-efficient windows that can reduce heating and cooling costs.

Flooring materials made from recycled PVC are also valuable for their durability and ease of maintenance. These materials are used in both residential and commercial buildings, offering a cost-effective and resilient flooring solution.

Manufacture of Consumer Goods

Recycled PVC finds applications in the manufacture of a variety of consumer goods, contributing to sustainable product cycles.

In the field of toys, recycled PVC is shaped into safe and durable products. This application is critical in reducing the environmental impact of plastic waste while ensuring that toys are long-lasting.

Extrusion processes use recycled PVC to create items such as garden hoses and traffic cones. These products benefit from the material’s flexibility and strength, making them ideal for outdoor and demanding uses.

Additionally, recycled PVC is employed in producing cable insulation for electrical wiring. This application ensures that wiring is safe and protected, optimizing performance and extending the lifespan of electrical systems.

Recycling PVC into these products not only helps in waste reduction but also in creating sustainable, long-lasting, and efficient consumer goods.

Environmental Benefits and Sustainability

PVC scrap material offers significant environmental benefits and contributes to sustainability in several impactful ways. These benefits include reducing the carbon footprint associated with production and disposal, and supporting the circular economy through recycling and reuse.

Reduction of Carbon Footprint

Recycling PVC scrap material significantly lowers the carbon footprint of PVC production. Processing recycled PVC consumes less energy compared to producing virgin PVC. This reduction in energy usage decreases greenhouse gas emissions.

Using recycled PVC also reduces the demand for virgin raw materials, such as oil and gas. This conservation of natural resources further diminishes the overall carbon emissions. By opting to recycle, industries can cut down the levels of pollutants released into the air.

Recycled PVC also means less material ending up in landfills. Diverting waste from landfills minimizes methane emissions from decomposition. Methane is a potent greenhouse gas that contributes to climate change.

Supporting the Circular Economy

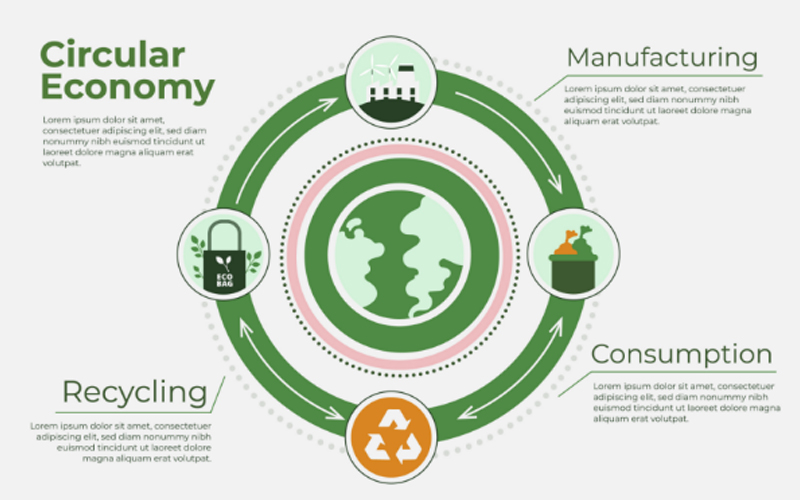

Recycling PVC scrap material plays a critical role in the circular economy. In a circular economy, materials are continually reused and recycled, which minimizes waste and maximizes resource efficiency.

PVC’s durability and versatility make it an ideal candidate for recycling. It can be processed and reformed into various products multiple times without significant degradation of quality. Common products made from recycled PVC include flooring, pipes, and automotive parts.

This continuous recycling loop helps reduce the need for new raw materials. It also keeps PVC out of landfills, contributing to eco-friendly waste management practices.

Recycling initiatives promote sustainable practices in industries, encouraging businesses to adopt eco-friendly approaches. This shift to sustainable manufacturing practices benefits both the environment and the economy.