Polyvinyl chloride, commonly known as PVC, stands as one of the most widely used synthetic polymers in the world. Due to its versatility, it finds applications across a multitude of industries, from construction and medical devices to automotive components and beyond. Integral to its usefulness is its stability, which is not inherently robust under heat and processing conditions. This is where PVC stabilizers play a crucial role; they are chemical compounds that enhance the thermal and mechanical properties of PVC, ensuring it maintains its desired characteristics during and after the manufacturing process.

Heat stabilizers are particularly important because PVC tends to degrade when exposed to high temperatures, a common scenario during processing. This thermal instability can lead to discoloration, loss of mechanical strength, and an overall decline in performance. Stabilizers address these challenges by neutralizing free radicals formed during heating, thus protecting the material from breakdown and extending its lifespan. Through the use of PVC stabilizers, the material acquires essential properties such as resistance to heat distortion while retaining the flexibility and durability that make it valuable in various applications.

Definition of PVC Stabilizers

PVC stabilizers are chemical compounds that are added to polyvinyl chloride (PVC) to enhance its material properties and prolong its usable lifespan. These additives play a critical role in maintaining the integrity of PVC through various conditions.

- Thermal Stability: Stabilizers are essential in preventing the thermal degradation of PVC at high temperatures during processing.

- Mechanical Properties: Stabilizers also bolster the overall strength of PVC, helping to avert brittleness and cracks.

- Chemical Resistance: They contribute to the chemical durability of PVC, protecting it against acids, bases, and other corrosive elements.

- Processability: The presence of stabilizers greatly improves the ease with which PVC can be shaped and manufactured.

Types of PVC Stabilizers:

- Lead-based Stabilizers: Traditionally used but are being phased out due to environmental concerns.

- Calcium-based Stabilizers: An eco-friendly option that offers good stability.

- Tin-based Stabilizers: Provide excellent transparency and are often used in applications requiring high clarity.

The stabilizers’ function is not just confined to protection during manufacturing but extends to the end product, ensuring longevity and reliability. Without these stabilizers, PVC products would be less resilient to external and internal stresses, leading them to degrade much more rapidly.

Types of PVC Stabilizers

In the realm of polyvinyl chloride (PVC) manufacturing, stabilizers are crucial for enhancing the material’s properties and extending its usability. They ensure PVC’s thermal stability, and chemical resistance and prevent early degradation. Each type of PVC stabilizer serves a specific purpose, tailored to improve various attributes of PVC in different applications.

Lead-Based Stabilizers

Lead-based stabilizers are among the oldest types utilized in PVC applications. They are highly effective in providing thermal stability and maintaining the material’s rigidity. However, due to environmental and health concerns, their use is declining in favor of more eco-friendly alternatives.

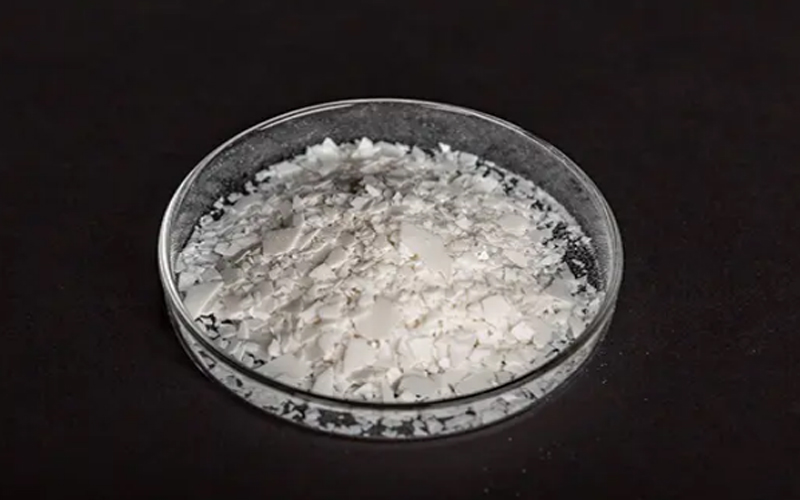

Calcium-Based Stabilizers

Calcium-based stabilizers are a popular choice for PVC window profiles, pipes, and fittings. They are not only efficient in stabilizing PVC but also offer significant environmental benefits over lead-based options. Their non-toxic nature makes them a preferred choice in many applications.

Tin-Based Stabilizers

Tin-based stabilizers are predominantly used for their superb clarity and transparency, making them ideal for PVC packaging film and bottles. These types of stabilizers also contribute to the material’s heat stability, a vital factor for processes involving high temperatures.

Barium-Based Stabilizers

Stabilizers containing barium are commonly used in flexible PVC products due to their excellent lubricating properties. They play a key role in improving the processing characteristics of PVC and are often used in concert with other stabilizers to produce compounds with enhanced functionality.

Organotin Stabilizers

Organotin stabilizers are highly efficient and are primarily used in rigid, high-performance applications such as PVC pipes and outdoor products. Their effectiveness at low concentrations and resistance to weathering make organotin stabilizers a valuable component of the PVC manufacturing process.

Functions of PVC Stabilizers

PVC stabilizers are critical additives that enhance the performance and longevity of PVC products. They play essential roles in managing the heat sensitivity of PVC and ensuring its utility across various applications.

Heat Stabilization

Heat stabilizers are crucial as PVC is inherently heat sensitive, which can lead to degradation when processed at high temperatures. These additives intercept harmful chloride ions and free radicals formed during the PVC’s thermal exposure, preventing material breakdown. The result is a product able to withstand thermal processes without compromising structural integrity.

Processing Stabilization

During processing, stabilizers facilitate smoother handling and manufacturing of PVC products. They improve the melt flow and ensure consistency, enabling the PVC to be more easily shaped and transformed into the desired form. This stabilization is particularly vital during extrusion, molding, and compounding.

Functions of PVC Stabilizers

PVC stabilizers are critical additives that enhance the performance and longevity of PVC products. They play essential roles in managing the heat sensitivity of PVC and ensuring its utility across various applications.

Heat Stabilization

Heat stabilizers are crucial as PVC is inherently heat sensitive, which can lead to degradation when processed at high temperatures. These additives intercept harmful chloride ions and free radicals formed during the PVC’s thermal exposure, preventing material breakdown. The result is a product able to withstand thermal processes without compromising structural integrity.

Processing Stabilization

During processing, stabilizers facilitate smoother handling and manufacturing of PVC products. They improve the melt flow and ensure consistency, enabling the PVC to be more easily shaped and transformed into the desired form. This stabilization is particularly vital during extrusion, molding, and compounding.

Color Stability

Stabilizers contribute to color stability in PVC, preventing discoloration that can occur with heat and light exposure. For aesthetic and functional purposes, maintaining proper coloration is important, especially for consumer products and visible components. Additives keep the original hue intact over time and use.

Long-Term Durability

Ensuring long-term durability is another significant function of PVC stabilizers. These additives protect against oxidative degradation, which can lead to a loss in mechanical strength and flexibility. By doing so, they extend the product’s lifespan and maintain performance, especially in applications where PVC is exposed to varying environmental conditions.

Applications of PVC Stabilizers

PVC Stabilizers play a crucial role in enhancing the properties and extending the life of PVC products. They are incorporated into various PVC applications to prevent degradation and maintain material integrity.

Pipes and Fittings

PVC stabilizers are integral to the production of pipes and fittings. They impart the necessary thermal stability during processing and ensure that the final products can withstand environmental stress over long periods. Stabilizers protect against the harsh effects of weather, chemicals, and the materials transported within the pipes, preventing material failure.

Cables and Wires

In cables and wires, PVC stabilizers contribute to the flexibility and durability of the insulation and sheathing. The additives maintain the cables’ insulating properties and prevent premature aging due to heat and electrical stress. This application demands stabilizers that also preserve the material’s non-conductive properties.

Profiles and Panels

Profiles and panels, such as those used in window frames and doors, rely on PVC stabilizers for resistance to UV radiation and weathering. The stabilizers enhance the material’s color stability and impact resistance, key factors for maintaining the aesthetic and structural aspects of these applications.

Flooring and Wall Coverings

For flooring and wall coverings, PVC stabilizers ensure that the material remains resilient against wear and abrasion. They also provide the flexibility required for easy installation and contribute to the product’s longevity by resisting stains, impacts, and moisture.

Choosing the Right PVC Stabilizer

When selecting a PVC stabilizer, it is pivotal to consider the specific requirements of the PVC formulation and the intended application. The stabilizer must ensure thermal stability, UV resistance, and color stability to enhance the longevity and durability of the product.

Factors to Consider:

- Processing Temperature: Higher processing temperatures may require stabilizers with excellent heat resistance.

- Product Characteristics: Desired properties like flexibility, clarity, and impact resistance dictate stabilizer choice.

- Environmental Factors: Some applications may need stabilizers that are non-toxic or lead-free to meet safety standards.

Types of PVC Stabilizers:

- Lead-based Stabilizers: Traditionally used but now being phased out due to toxicity concerns.

- Calcium-zinc Stabilizers: A popular choice for their non-toxic nature and versatility.

- Organotin Stabilizers: Often used for their effectiveness in rigid PVC applications.