Polyvinyl chloride, commonly known as PVC, is a versatile and widely used material in industries ranging from construction to consumer goods. Stabilizers are added to PVC formulations to enhance thermal stability and prevent degradation, ensuring the longevity and durability of the material. There are various types of stabilizers used in PVC applications, each offering distinct benefits. These stabilizers not only provide effective heat stabilization but also improve the environmental footprint of PVC products.

Types of PVC Stabilizers

PVC stabilizers are critical for enhancing the polymer’s heat stability and processability. These additives help prevent degradation during processing and extend the material’s lifespan. Below are details about common types of stabilizers used in PVC, highlighting their unique characteristics and benefits.

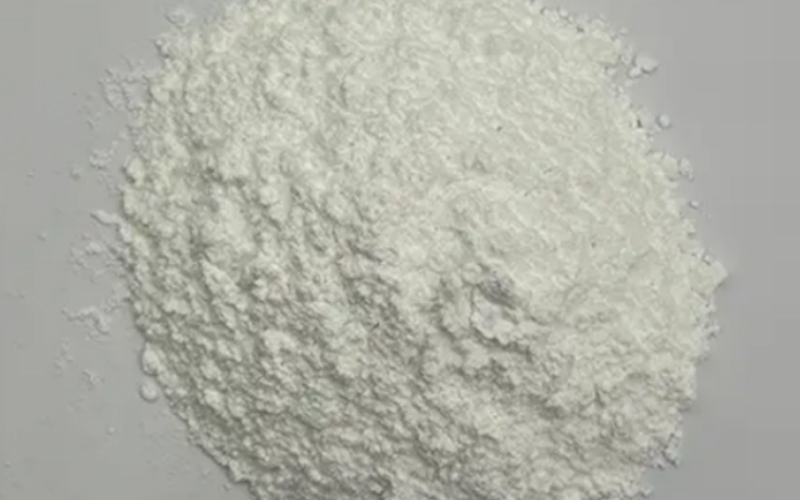

Lead Stearate

Lead stearate is a prevalent type of lead-based stabilizer used in PVC applications. It is particularly effective in providing heat stability and lubrication properties. By forming a barrier, it minimizes heat-induced degradation.

Calcium-Zinc Stabilizers

Calcium-zinc stabilizers are widely adopted as more environmentally friendly alternatives compared to lead-based options. These stabilizers offer excellent heat stability and transparency, making them ideal for both rigid and flexible PVC applications. They contain organic stabilizers that further enhance performance without harmful side effects. Their growing popularity is driven by a combination of performance benefits and compliance with global regulatory standards for safety.

Barium-Cadmium Stabilizers

Barium-cadmium stabilizers provide exceptional heat and light stability, properties that are critical for outdoor applications of PVC. They work well in transparent applications due to their low color yield.

Barium Zinc Stabilizers

Barium-zinc stabilizers are valued for their superior thermal stability and dynamic processing heat stability. These stabilizers enhance the overall durability of PVC, particularly in extrusion and injection molding processes. They offer a balanced heat and shear stability, making them versatile for diverse PVC formulations. The inclusion of zinc helps in maintaining good initial coloration and preventing discoloration during processing, supporting various aesthetic requirements.

Applications of PVC Stabilizers

PVC stabilizers play a crucial role in extending the lifespan and enhancing the performance of PVC across various industries. They help improve thermal stability, UV resistance, and durability, making PVC suitable for diverse applications from construction to healthcare.

Construction Applications

In the construction industry, PVC stabilizers are widely used to enhance the durability and longevity of infrastructure components. PVC compounds treated with stabilizers are commonly found in pipes and window profiles, critical for plumbing and water systems. These stabilizers ensure that the PVC maintains its integrity under temperature fluctuations and exposure to sunlight, providing reliable performance over time.

Flexible PVC in roofing membranes benefits from stabilizers, which help maintain flexibility and resistance to weather-related deterioration. Overall, these applications in construction demonstrate the effectiveness of stabilizers in enabling PVC to meet the high-performance standards required in such essential infrastructure.

Packaging Applications

The packaging industry relies on PVC stabilizers to ensure the safety and quality of packaging materials. In food packaging, special PVC stabilizers preserve the freshness of products by preventing degradation from light and heat. Certain calcium zinc stabilizers are used in these applications to offer non-toxic alternatives suitable for contact with consumable goods.

PVC films benefit from stabilizers, which help maintain clarity and flexibility, crucial for effective and appealing packaging formats. This ensures that both protective and aesthetic qualities are retained.

Healthcare and Medical Equipment

In healthcare, the stability and safety of medical equipment are paramount. PVC stabilizers are essential in manufacturing medical devices, such as tubing and blood bags, due to their ability to enhance thermal resistance and prevent material degradation.

These stabilizers ensure that equipment withstands sterilization processes without compromising structural integrity. PVC compounds in medical-grade applications are carefully formulated to avoid contaminants, safeguarding the reliability and safety of healthcare products used during patient care.

Automotive and Electronics Industry

PVC stabilizers are vital in the automotive industry where they help in manufacturing various interior and exterior components. These include dashboards, cable insulation, and sealants. Stabilizers enhance the heat and UV resistance of flexible PVC, which improves the durability of automotive parts under harsh conditions.

In the electrical and electronics industry, stabilizers ensure high-performance insulation and protection for wires and cables. They help maintain the plastic’s properties even at elevated temperatures, securing the safety and longevity of electronic devices.

Interior Design and Furniture

The interior design and furniture industry utilize PVC stabilizers to create long-lasting, aesthetic products. In flooring applications, stabilizers ensure that PVC compounds maintain their appearance and are resistant to scratches and stains.

The use of stabilizers in furniture production, such as in upholstery and wall coverings, supports the durability of flexible PVC materials. This ensures that design elements remain intact and attractive over time, making them both practical and visually appealing.

Properties Enhanced by PVC Stabilizers

PVC stabilizers play a crucial role in enhancing the performance and longevity of PVC products. They address issues such as thermal degradation and ultraviolet (UV) light exposure, ensuring that PVC maintains its structural and aesthetic properties over time.

Thermal and UV Stability

Stabilizers significantly improve the thermal stability of PVC by reducing its susceptibility to heat. Without stabilizers, heat causes PVC to degrade, resulting in the release of hydrochloric acid gas and the formation of free radicals. These stabilizers intervene by neutralizing these effects and preserving the polymer’s integrity. For applications exposed to light, UV stabilizers offer vital protection against UV radiation, preventing discoloration and material breakdown. By enhancing both thermal and UV stability, these additives extend the lifespan of PVC products used in a variety of environments.

Mechanical and Chemical Properties

PVC stabilizers also strengthen its mechanical properties, providing resistance to environmental stress and physical impacts. Additives ensure the material retains its flexibility and toughness over time. Chemical stabilizers offer increased chemical resistance, which is especially important when PVC is exposed to harsh chemicals. This provides the polymer with the durability required for industrial applications, increasing its usability in environments where chemical stability is a priority.

Flame Retardancy and Color Retention

Flame retardants are incorporated into PVC through specific stabilizers that reduce the material’s flammability. These substances work by inhibiting combustion processes, a necessity for applications requiring high safety standards. Similarly, color retention is greatly improved by stabilizers, preventing fading and maintaining color vibrancy over time. This is particularly important in outdoor applications where PVC is subject to constant sunlight, aided by UV stabilizers that keep colors intact.

Durability and Visual Appeal

The overall durability of PVC is enhanced through the use of stabilizers that mitigate degradation factors. These additives ensure that PVC maintains its structural integrity in various environmental conditions.

Furthermore, stabilizers contribute to the visual appeal of PVC by preserving surface quality and preventing surface imperfections like chalking or cracking. This is crucial for applications where aesthetics are as important as functional performance, ensuring that PVC products are both reliable and visually appealing.

PVC Stabilizer Selection and Processing

Selecting appropriate stabilizers in PVC ensures durability and performance. Stabilizers like metal soaps and antioxidants are used to protect PVC during processing. Important factors include processing conditions and the environmental impact of the stabilizers.

Impact on Processing and Performance

Proper selection of stabilizers can greatly influence the efficiency of PVC processing techniques, such as extrusion. Heat stabilizers are crucial in preventing melt deterioration during processing. They maintain the polymer’s integrity by avoiding degradation at high temperatures. Commonly used heat stabilizers include metal soaps and organic tin compounds, which cater to specific processing needs and desired product characteristics.

Light stabilizers are added to safeguard PVC from ultraviolet light exposure, prolonging the lifespan and maintaining the material’s properties. Additionally, antioxidants are sometimes used alongside heat stabilizers to further enhance the thermal stability.

Environmental and Health Considerations

The choice of PVC stabilizers affects not only product performance but also health and environmental safety. Historically, toxic stabilizers such as lead and cadmium were common, but concerns have led to their phase-out in regions like the EU. Presently, stabilizers are selected based on safer alternatives, including calcium-zinc and organic options.

The focus has shifted toward sustainable PVC formulations that consider both environmental impact and regulatory compliance. This shift encourages the use of stabilizers with lesser ecological footprints while maintaining their effectiveness in PVC processing applications. These decisions are crucial for meeting today’s processing and quality needs while being environmentally responsible.